SIDERISE® Cavity Barriers

Siderise have been developing bespoke fire, thermal and acoustic insulation solutions for over 40 years.

SIDERISE® have been developing bespoke fire, thermal and acoustic insulation solutions for over 45 years.

SIDERISE® Cavity Barriers allow for continuous ventilation and drainage behind the cladding while providing a hot smoke and fire seal. Siderise fire barriers are composed of a non-combustible stone wool lamella core, faced on exposed surfaces with a reinforced aluminium foil. This system includes products for both horizontal and vertical solutions.

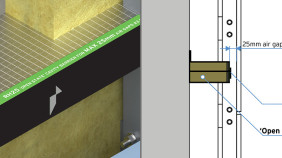

SIDERISE® RH ‘Open State’ horizontal cavity barriers are specifically used in drained a ventilated facade. The system will drain any moisture within the façade construction, as well as maintain airflow. The system will provide an effective an effective hot smoke and fire seal in the event of a fire. The SIDERISE® ‘Open State’ systems are available for air gaps of up to 25mm – RH25 and 50mm – RH50. SIDERISE® RH25 is suitable for use in cavities widths up to 425mm wide and RH50 for cavities up to 300mm.

SIDERISE® RV vertical cavity barriers fully seal the void between the external envelope and internal structure. The cavity barrier assists ventilated facades to function by maintaining air-pressurisation. The products unique stone wool lamella core enables the vertical barriers to accommodate movement associated with rainscreen facades. Intersections between horizontal and vertical cavity barriers are simply abutted.

SIDERISE® cavity barriers have been tested at Warrington-Fire and are 3rd Party Certified under EWCL5 (Certificate ME 5101). The barriers are available to suit 30, 60, 90 and 120 minute applications.

SIDERISE® Cavity Barriers are supplied in 1200mm long strips and can be pre-cut in width to suit advised void sizes.

The SIDERISE® RH ‘Open State’ reaction process in the event of a fire;

Click here to view – SIDERISE® Rainscreen Fire Barrier Data Sheet